Mercedes aluminum repair demands advanced techniques and certified professionals due to the unique properties of modern Mercedes vehicles. Specialized procedures like precise welding and computer-aided measurements ensure structural integrity and maintain original quality during collision damage repairs. Certified technicians use OEM methods and tools, guaranteeing aesthetic restoration and retention of safety and performance standards, setting top-tier auto repair shops apart from general bodyshops.

Mercedes aluminum repair is a specialized art that demands precision and expertise. With the increasing use of lightweight aluminum in Mercedes-Benz vehicles, understanding the unique repair process has become crucial. This article delves into the intricacies of Mercedes aluminum repair, highlighting the challenges posed by OEM components and the significance of using certified techniques. By exploring these aspects, we emphasize the importance of restoration methods that maintain the brand’s originality and quality.

- Understanding Mercedes Aluminum Repair Process

- Challenges in Repairing OEM Aluminum Components

- The Role of Certification in Restoring Mercedes' Originality

Understanding Mercedes Aluminum Repair Process

Mercedes aluminum repair is a specialized process that requires advanced knowledge and techniques due to the unique material properties of modern Mercedes vehicles. The first step in understanding Mercedes aluminum repair is recognizing that traditional steel-based car body repair methods do not always apply. Aluminum, being lighter and more malleable, demands specific procedures to ensure structural integrity and maintain the vehicle’s original quality.

Collision damage repair on Mercedes aluminum bodies necessitates precise techniques such as specialized welding, precision cutting, and computer-aided measurements. Auto repair shops that specialize in Mercedes aluminum repair employ OEM (Original Equipment Manufacturer)-certified methods and tools to handle complex panel replacements and structural repairs. This ensures that the car body repair not only restores the vehicle’s aesthetics but also retains its safety standards and performance capabilities.

Challenges in Repairing OEM Aluminum Components

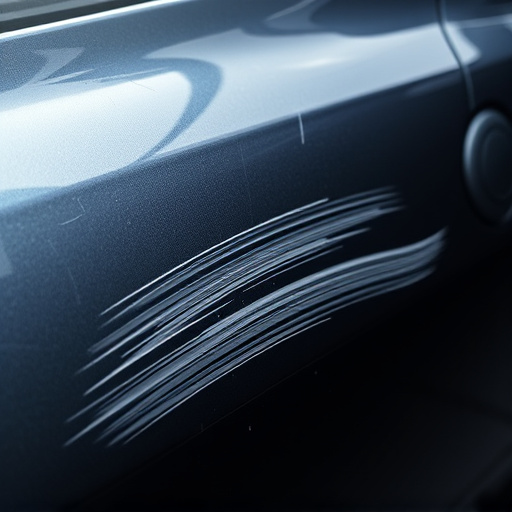

Aluminum is a lightweight and durable material widely used in modern automotive manufacturing, especially in premium brands like Mercedes. However, repairing OEM aluminum components presents unique challenges compared to traditional steel or plastic parts. One of the primary difficulties lies in the material’s inherent properties; aluminum is more susceptible to corrosion and can be challenging to weld or join without proper techniques and specialized equipment.

In a Mercedes aluminum repair, achieving a seamless and structurally sound result requires certified professionals equipped with advanced knowledge and skills. Traditional car paint services or general car repair shops may not have the necessary expertise, as aluminum repair techniques differ significantly from those used for other materials. This specialization is crucial to ensure that the repaired component maintains its structural integrity and aesthetic appeal, adhering to Mercedes’ high-quality standards. A collision center, for instance, should be equipped with OEM-certified methods to handle such delicate repairs effectively.

The Role of Certification in Restoring Mercedes' Originality

When it comes to Mercedes aluminum repair, certification plays a pivotal role in ensuring the originality and quality of the restoration process. With vehicles like Mercedes renowned for their precision engineering, using OEM (Original Equipment Manufacturer) certified techniques is crucial. These specialized methods guarantee that every component, from replacement parts to repair procedures, aligns perfectly with the vehicle’s original design and specifications.

Autobody repairs involving aluminum require a deep understanding of material properties and unique restoration techniques. Certified technicians are trained to handle these intricate processes, ensuring precise measurements, seamless panel fitting, and structural integrity. This level of expertise is vital not only for maintaining the vehicle’s aesthetic appeal but also for its long-term performance and safety, setting apart a top-notch auto repair shop from the rest in the market, including those offering services for auto glass repair or general autobody repairs.

Mercedes aluminum repair, due to its intricate nature and focus on maintaining vehicle originality, demands specialized techniques and OEM-certified professionals. The challenges posed by unique OEM aluminum components necessitate advanced training and precise tools. By embracing certification, restorers can confidently deliver repairs that meet Mercedes’ high standards, ensuring a seamless blend of performance and aesthetics for these prestigious vehicles.